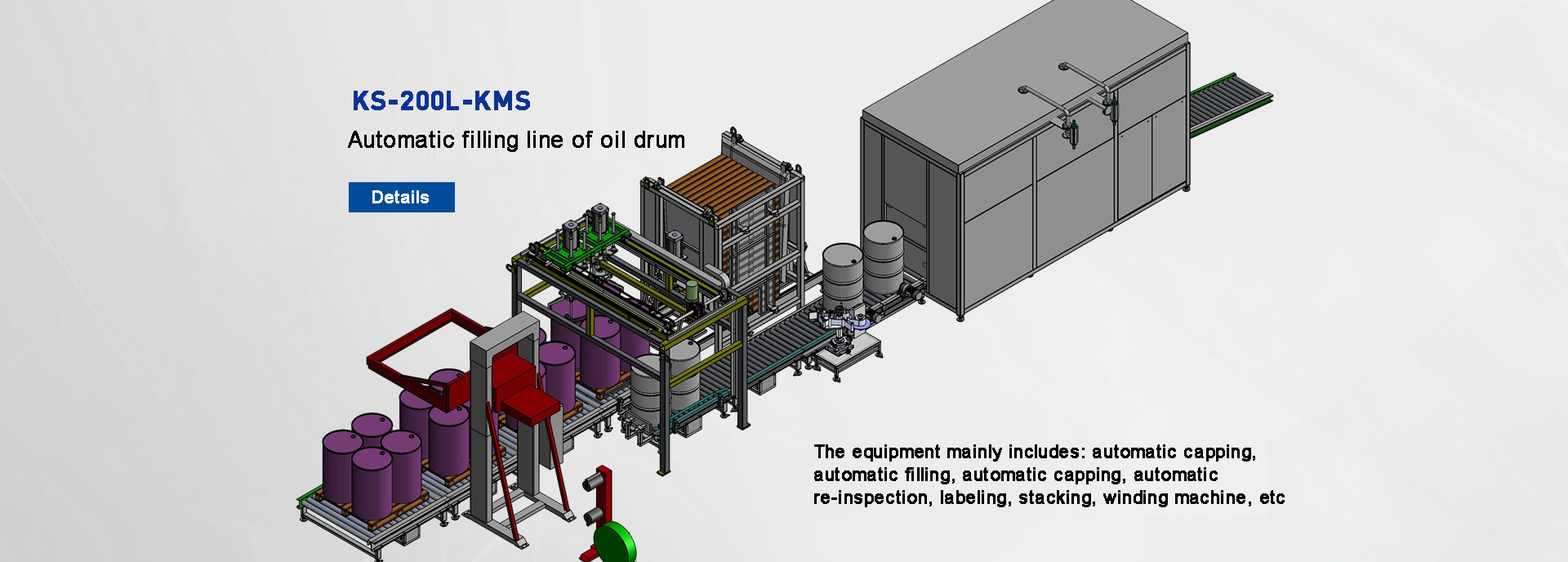

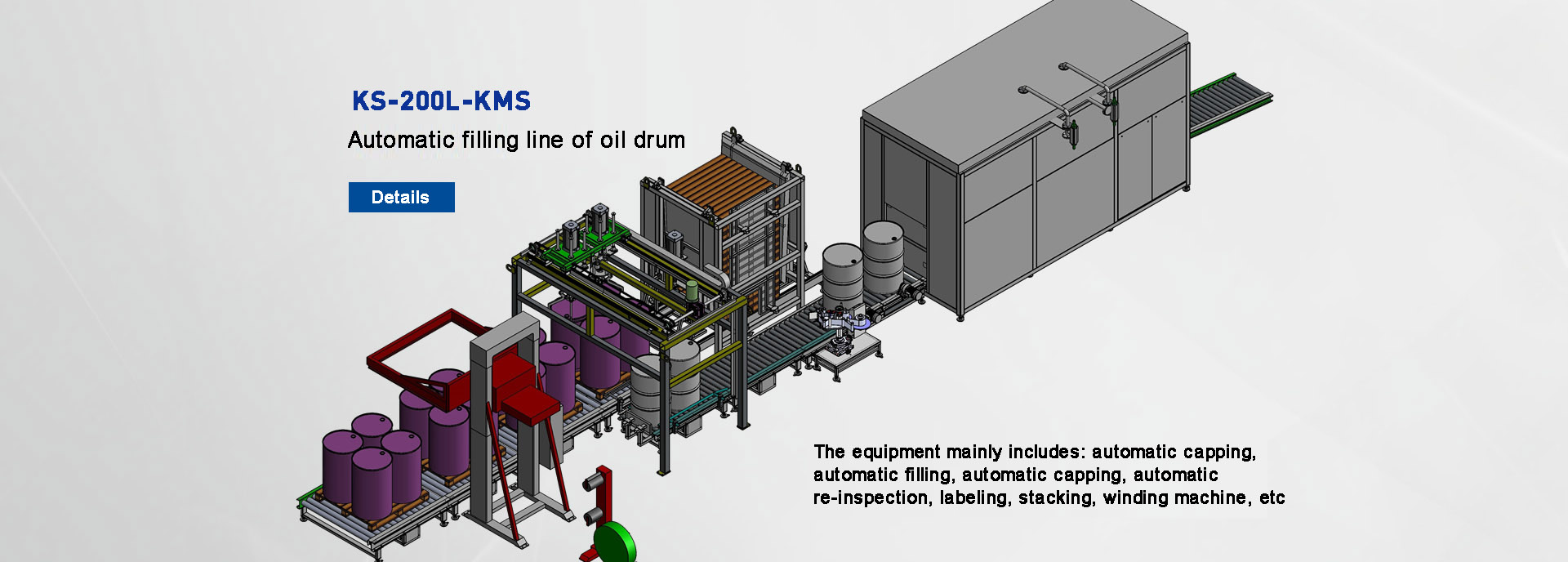

Automatic Pail Filling System

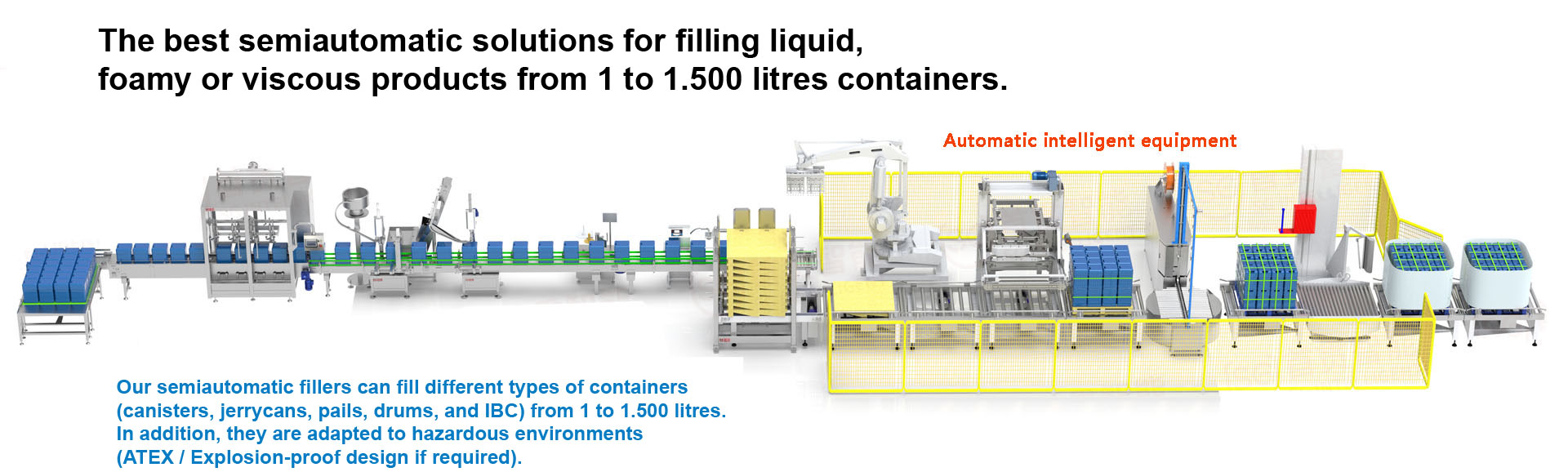

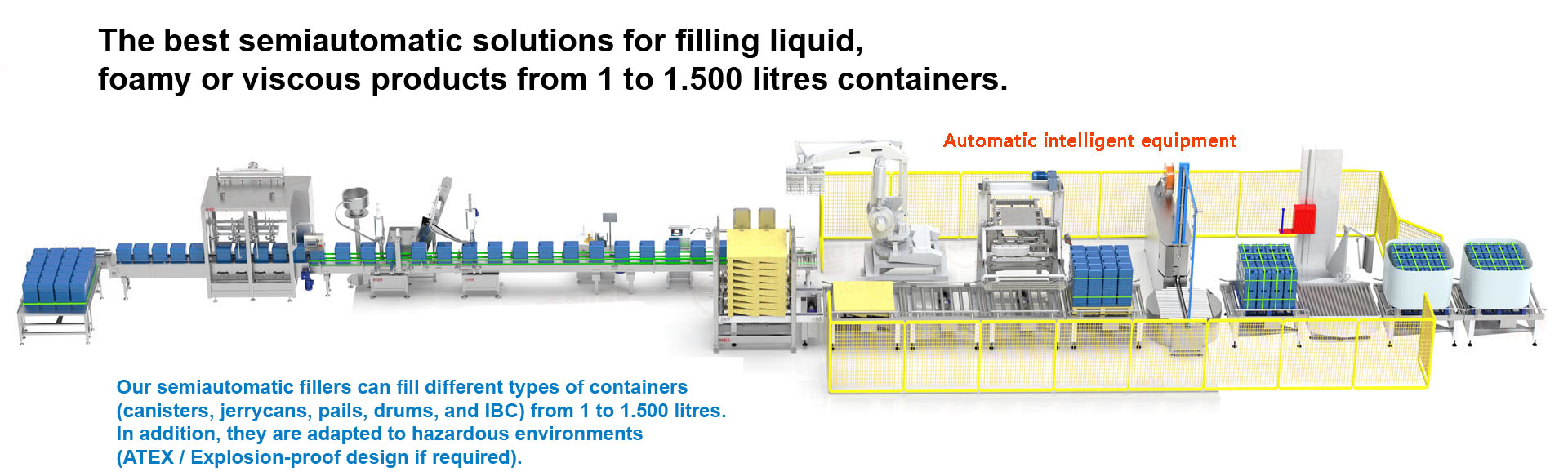

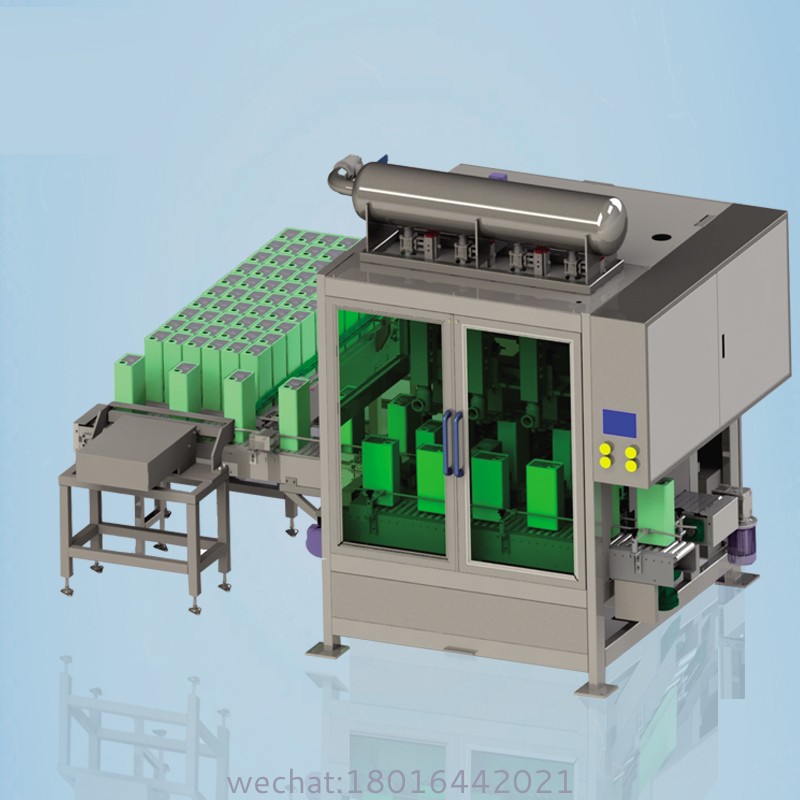

This machine is an intelligent packaging system designed for the packaging of 200L barrels and 1000L ton barrels of liquids in explosion-proof environments. It is used for the packaging of 200L barrels and 1000L ton barrels (including pallets). It is often used to store and transport liquids or bulk materials, such as chemicals, lubricants, coatings, food raw materials, etc. The main function of the ton barrel filling machine is to extract liquids or bulk materials from storage containers or tanks. Using visual port finding, it can realize the automatic opening, automatic diving, automatic fast and slow filling, automatic leakage detection, automatic sealing of threaded caps and other process automation packaging of 200L barrels and 1000L ton barrels. The filling host part adopts an environmentally friendly outer frame, a visual window, and an automatic lifting and sliding door for entering and exiting the barrel, which can form a closed space during filling. The electrical control part of this machine is composed of a PLC programmable controller, a weighing module, a visual system, etc., with strong control capabilities and a high degree of automation. The PLC is equipped with an Ethernet communication interface, which can communicate with the owner's system. This machine has the functions of not filling without a barrel, not filling if the barrel mouth is not aligned, etc., which avoids the waste and pollution of materials and makes the mechatronics of the machine well demonstrated.

The working principle of weighing is used to control the filling volume. During filling, the programmable controller PLC controls the opening time of the filling valve, and the material flows into the container to be filled by itself (or is fed by the pump). The filling part of this machine realizes the filling flow rate control through the manual valve + dual-channel fast and slow filling pneumatic ball valve, and the double-stroke switch of the filling Filling nozzle. During filling, the action of fast filling first and slow filling later can be realized, or the filling action of slow filling first, fast filling in the middle, and finally flooding can be realized. After the filling is completed, the automatic screw capping and waterproof capping action are performed. The equipment has functions such as alarm mechanism, fault display, prompt processing plan, etc. The filling line has the function of interlocking protection of the whole line. The filling stops automatically when there is no barrel, and the filling resumes automatically when the barrel is in place. The machine is equipped with a whole machine cover, a door for automatic opening and closing of the single-side equipment for entering and exiting the barrel, which automatically opens and closes when entering and exiting the barrel, and remains closed during filling. The rest is a closed structure with a window and a VOC exhaust interface for connecting to the owner's VOC ventilation system, and the packaging equipment maintains a negative pressure state inside.

The control system consists of a touch screen, PLC, and industrial computer. It has functions such as system self-checking, fault display alarm, and display of individual equipment status, accuracy, speed, and output. Each system has its own human-machine interface, and all parameters can be operated on the human-machine interface. Provide detailed flow charts and logic diagrams of the assembly line control process. It can store the type of filling materials, quantity batch, date, weight per barrel, storage time and other recording functions. The barrel mouth positioning is output by the visual camera after shooting the barrel mouth. The barrel mouth XY axis positioning coordinate parameters are output. The servo motor drives the filling Filling nozzle to move to the barrel mouth and then automatically dives into the barrel for filling. During filling, the Filling nozzle automatically rises with the rise of the liquid level. The filling Filling nozzle is hollow in design, and the material hanging wire can be purged after the Filling nozzle is closed to prevent material splashing. There is a liquid collecting tray at the bottom of the filling Filling nozzle. After the filling is completed, the filling head rises and the leak collecting tray extends out to prevent the material from contaminating the packaging and the conveying line. The liquid collecting tray is designed to be disassembled by hand without tools, which is convenient for cleaning. This machine is designed with two sets of coarse and fine Filling nozzles and a capping device for different barrel types with different material viscosities. The two different Filling nozzles and capping heads are automatically switched according to different barrel types through preset programs.