Auto Weighing Multi-Function Packing Machine for Packaging Food Powder, Cement

Auto Weighing Multi-Function Packing Machine for Food Powder & Cement

Overview

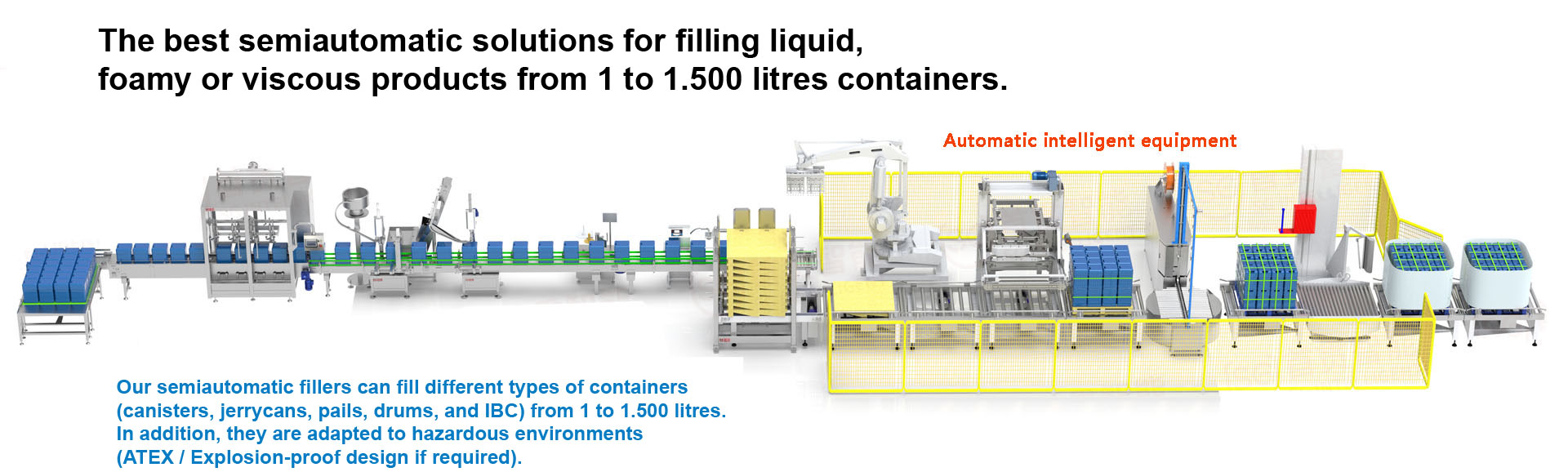

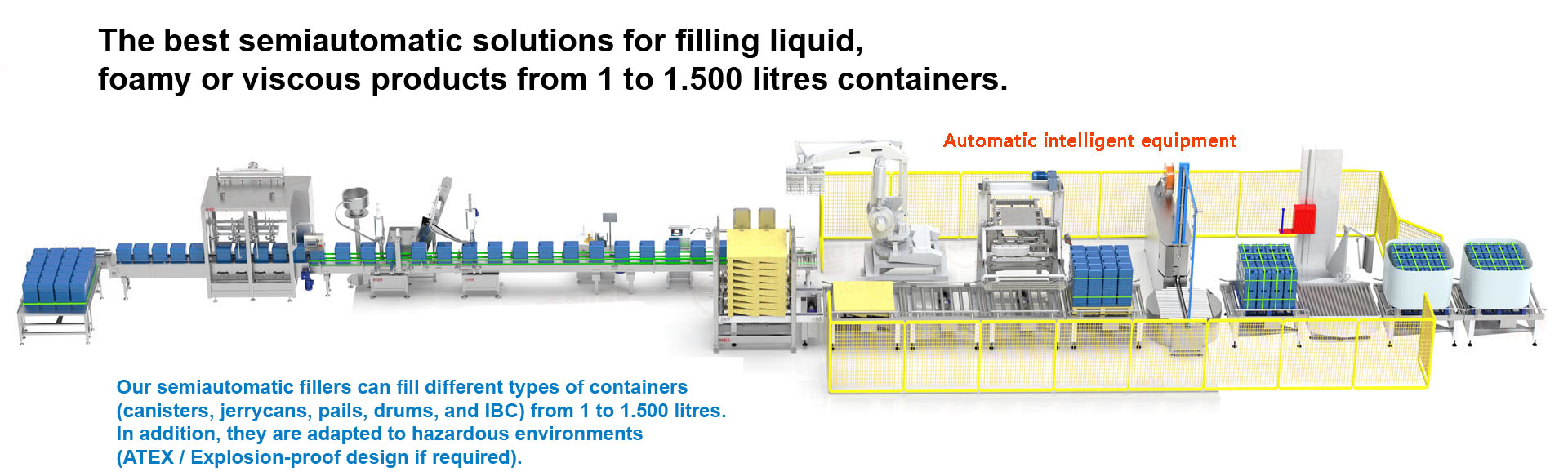

The Auto Weighing Multi-Function Packing Machine is a versatile, high-efficiency solution designed for precise weighing and packaging of both food powders (e.g., milk powder, spices, flour) and industrial materials like cement. With advanced weighing systems, dust control, and customizable configurations, it ensures accurate, hygienic, and efficient packaging for diverse products.

Key Features

Automated Weighing & Filling

Precision Weighing: High-accuracy load cells (±0.2–0.5% error) ensure consistent filling weights.

Adjustable Weight Settings: Quickly set target weights via HMI (Human-Machine Interface).

Multi-Product Compatibility

Food Powders: Stainless steel (304/316L) construction meets food-grade hygiene standards.

Cement & Industrial Materials: Robust wear-resistant components handle abrasive materials.

Dust Control & Contamination Prevention

Enclosed System: Dust-tight design with integrated dust extraction or vacuum cleaning.

IP65 Protection: Protects electrical components from dust and moisture.

Flexible Packaging Options

Bag Types: Supports pillow bags, standup pouches, spout pouches, or valve bags.

Sealing: Hermetic sealing for food powders; optional heavy-duty sealing for cement.

User-Friendly Operation

Touchscreen Interface: Easy recipe setup, weight adjustment, and production monitoring.

Semi-Automatic Design: Manual bag loading with automated weighing, filling, and sealing.

High Efficiency & Safety

Speed: Up to 20–30 bags/minute (depends on product and bag size).

Safety Features: Emergency stop, overload protection, and anti-vibration mounts.

Technical Specifications

Weighing Range: 10g–5kg (customizable for larger or smaller ranges).

Accuracy: ±0.2%–0.5% (adjustable for high-precision applications).

Materials:

Food Powders: Stainless steel (304/316L) with PTFE coatings (optional).

Cement: Wear-resistant steel with abrasion-proof coatings.

Power: 220V/50Hz or 110V/60Hz (energy-efficient).

Certifications: CE, ISO, and optional FDA/GMP compliance for food applications.

Applications

Food Industry: Milk powder, infant formula, spice mixes, flour, instant drink mixes, and nutritional powders.

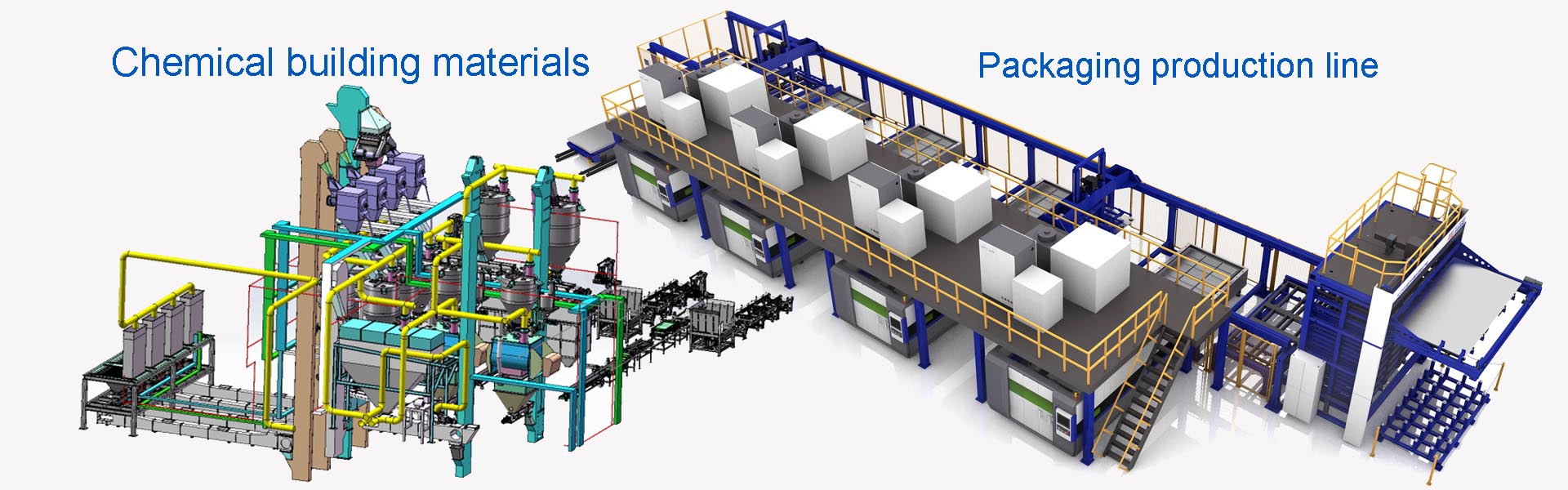

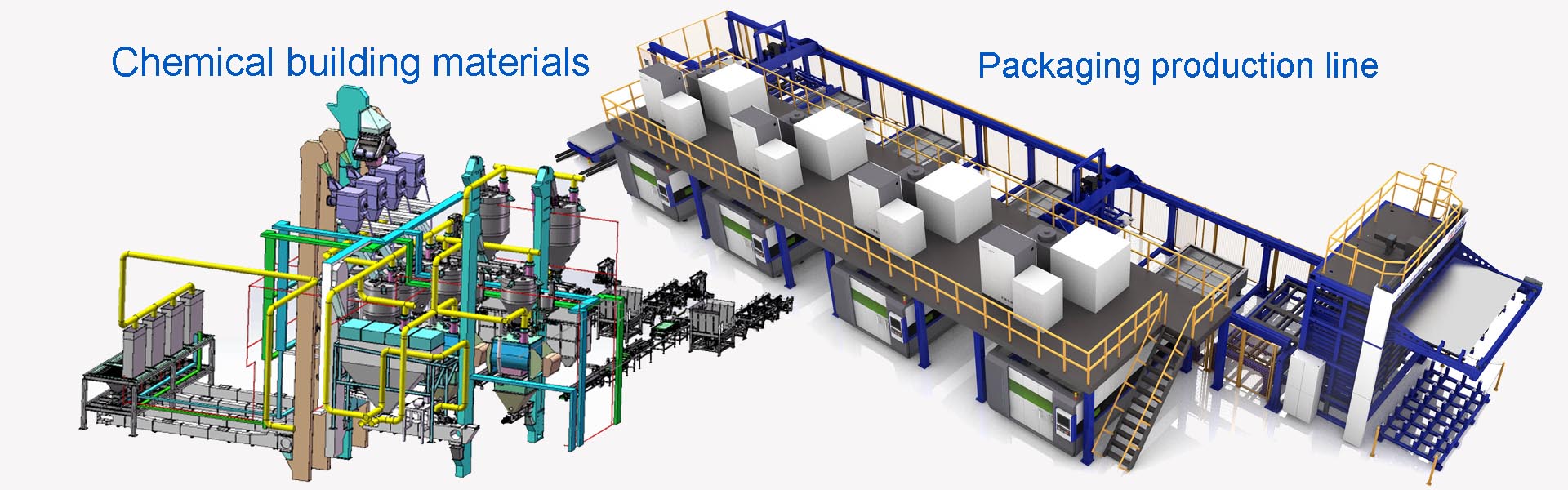

Construction & Industrial: Cement, sand, plaster, dry mortar, and chemical powders.

Pharmaceuticals: Powdered medications and supplements (with optional dust control).

Operation Steps

Bag Loading: Place an empty bag on the weighing platform.

Auto Weighing: The machine dispenses the product while continuously weighing in real time.

Filling & Sealing: Once the target weight is reached, the bag is sealed automatically.

Dust Extraction: Optional dust collection system minimizes contamination (critical for cement).

Repeat: Continue for batch processing or switch between products.

Optional Features

Dust Collection System: HEPA filters or cyclonic collectors for dusty materials like cement.

Nitrogen Flushing: Prevents oxidation in food powders during sealing.

Date/Batch Printing: Integrated thermal transfer printer for expiration dates and batch codes.

Vibration Feeder: For consistent flow of powdered materials into the weighing hopper.

Remote Monitoring: IoT connectivity for tracking performance and predictive maintenance.

Benefits

Versatility: Single machine for both food and industrial applications.

Precision & Reliability: Accurate weighing reduces product giveaway and waste.

Hygiene & Safety: Food-grade materials and dust control meet strict regulatory requirements.

Low Maintenance: Durable construction and quick-change parts minimize downtime.

Cost-Efficiency: Reduces labor costs and material waste compared to manual packing.

Why Choose This Machine?

This Auto Weighing Multi-Function Packing Machine combines precision, hygiene, and durability to handle the unique challenges of food powders and industrial materials like cement. Its modular design allows customization for your specific needs, ensuring efficient, compliant, and reliable packaging.

Contact us today for a tailored solution!

Immediate Order:

Website: http://www.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com