Semi Automatic Machine

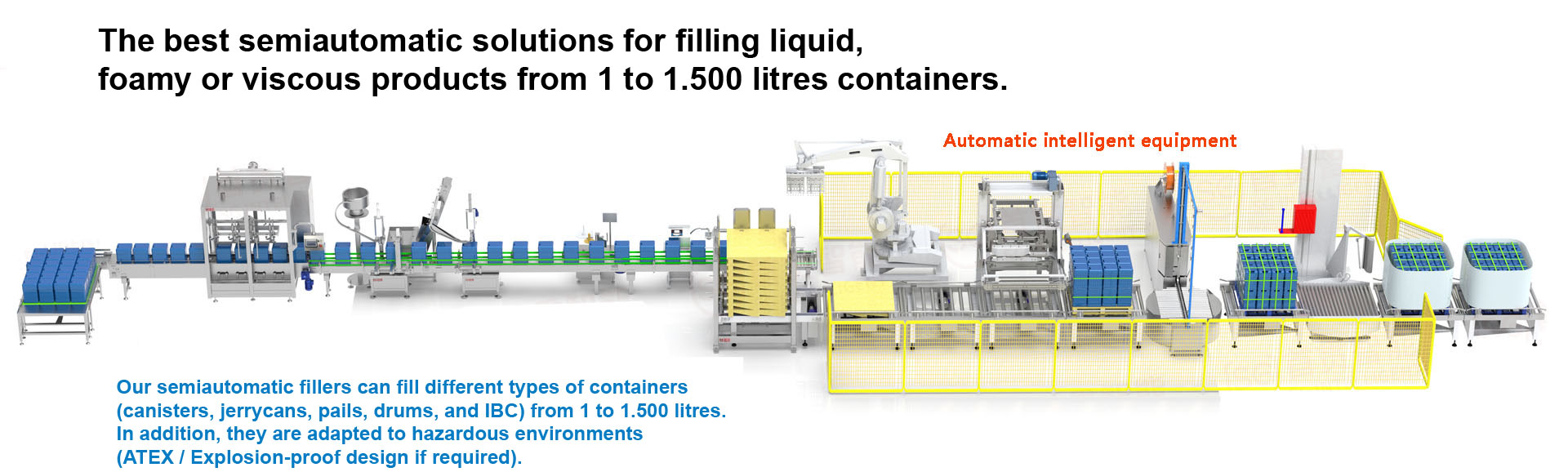

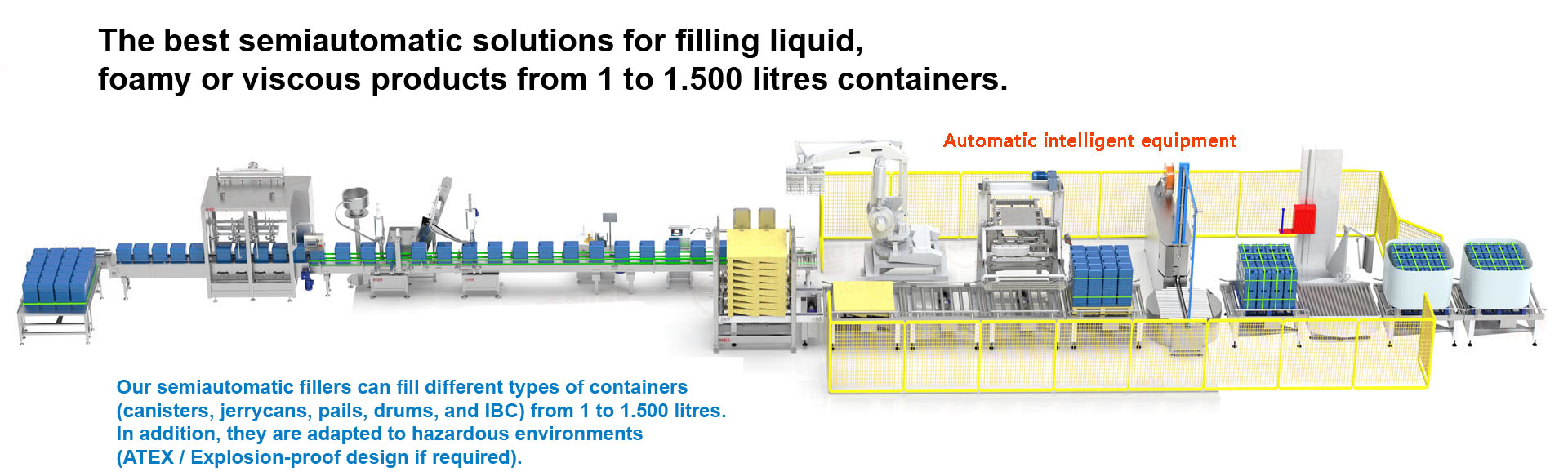

The Dual-Head 10L Semi-Auto Filling Machine with Synchronized Weighing is a high-efficiency solution designed for filling liquids into containers like jerry cans or drums with neck diameters ranging from 20mm to 150mm. Its dual-head design and synchronized weighing system make it twice as fast as single-head machines, while ensuring accuracy and reliability. Below is a detailed overview of its features, benefits, applications, and key considerations.

Key Features:

Dual-Head Design:

Two independent filling heads allow for 2x faster filling compared to single-head machines.

Ideal for high-volume production or large-scale operations.

Synchronized Weighing System:

Integrated weighing technology ensures precise and consistent filling volumes.

Each head is equipped with load cells to monitor and adjust the filling process in real-time.

10L Capacity:

Suitable for filling containers up to 10 liters (e.g., jerry cans, drums, or IBCs).

Customizable for smaller or larger volumes based on requirements.

Versatile Neck Diameter Compatibility:

Accommodates container necks ranging from 20mm to 150mm, making it suitable for a wide range of containers.

Adjustable nozzles ensure a secure fit and minimal spillage.

Semi-Automatic Operation:

User-friendly interface with touchscreen controls for easy setup and operation.

Manual placement of containers with automated filling and stopping.

High Accuracy:

Precision filling with ±0.5% accuracy, reducing product waste and ensuring consistency.

Suitable for viscous or non-viscous liquids, including chemicals, oils, and food products.

Hygienic Design:

Constructed from stainless steel (304/316) for durability and corrosion resistance.

Easy to clean and sanitize, meeting food and pharmaceutical industry standards.

Safety Features:

Overfill protection to prevent spills and product loss.

Emergency stop buttons and safety interlocks for operator protection.

Grounding and static-dissipative materials to prevent sparks or electrical hazards.

Customizable Speed and Flow Rate:

Adjustable flow rates and filling speeds to accommodate different products and container sizes.

Suitable for both fast and slow filling applications.

Data Logging and Integration:

Optional data logging for tracking fill volumes, batch numbers, and operator activity.

Compatible with PLC systems and can be integrated into larger automation workflows.

Benefits:

Efficiency: Dual-head design and synchronized weighing enable 2x faster filling, reducing production time and labor costs.

Precision: High accuracy ensures consistent fill volumes, minimizing product waste and rework.

Versatility: Suitable for a wide range of container sizes and liquid types, making it adaptable to various industries.

Safety: Robust safety features protect operators and prevent product contamination.

Cost-Effective: Reduces downtime and increases throughput, maximizing return on investment.

Applications:

Chemical Industry: Filling solvents, acids, bases, or other industrial chemicals into drums or IBCs.

Oil and Lubricants: Packaging engine oil, hydraulic oil, or grease into jerry cans or drums.

Food and Beverage: Filling sauces, syrups, or beverages into containers for storage or distribution.

Pharmaceuticals: Packaging liquid medications or formulations into sterile containers.

Agriculture: Filling pesticides, fertilizers, or other agrochemicals into drums or IBCs.

Logistics and Distribution: Bulk filling of liquids for shipping or storage.

Operation Steps:

Container Placement:

The operator manually places the container under the filling nozzle.

Automatic Filling:

The machine detects the container and initiates filling using the synchronized weighing system.

The dual-head design allows for two containers to be filled simultaneously.

Precision Stopping:

The machine stops filling once the desired volume is reached, ensuring accuracy and minimal spillage.

Container Removal:

The filled container is removed, and the next one is placed for continuous operation.

Cleaning and Maintenance:

The machine is easily cleaned between batches to prevent cross-contamination.

Routine maintenance ensures optimal performance and longevity.

Why Choose This Machine?

The Dual-Head 10L Semi-Auto Filling Machine with Synchronized Weighing offers a reliable, efficient, and precise solution for filling liquids into containers of various sizes. Its dual-head design, high accuracy, and versatility make it ideal for industries requiring high-volume, consistent, and safe liquid filling. Whether you’re in the chemical, food, pharmaceutical, or agricultural sectors, this machine provides a cost-effective way to meet your production needs.

For customization or technical assistance, consult with suppliers like GLZON or other reputable manufacturers to ensure the machine meets your specific requirements.

Immediate Order:

Website: http://www.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com