High-Speed Semi-Automatic Liquid Pail Filling Machine for Paint

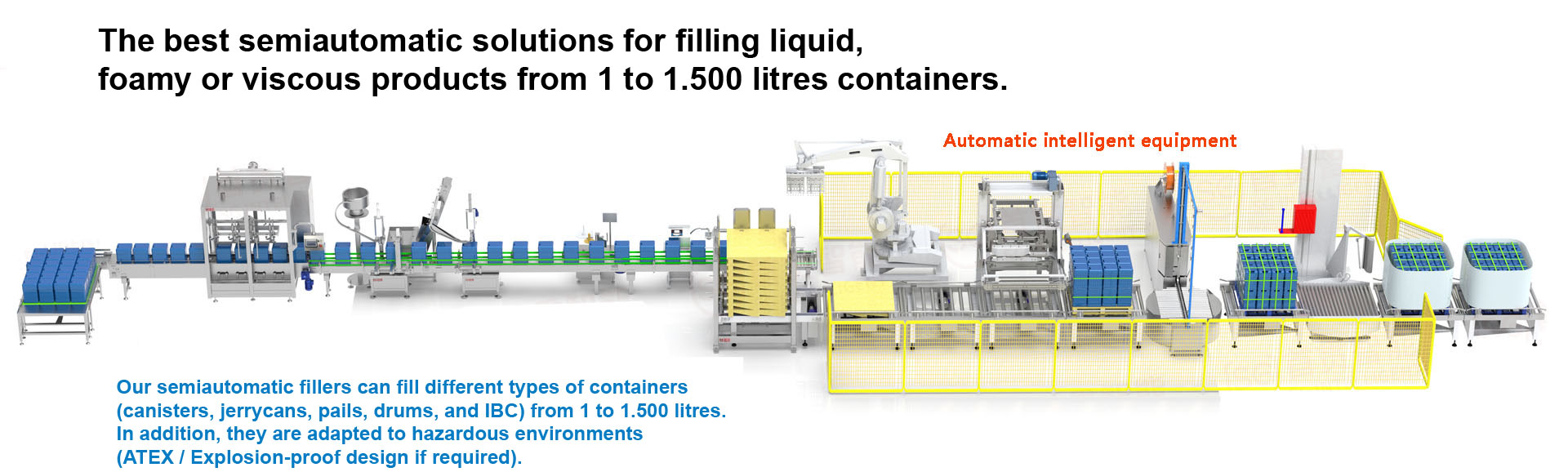

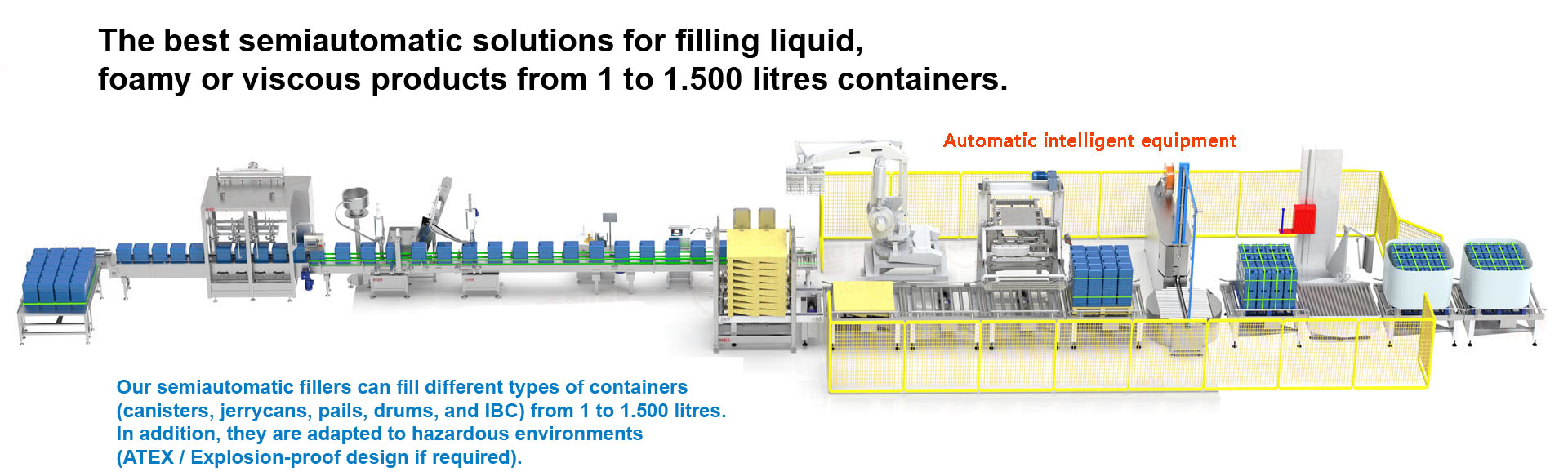

A High-Speed Semi-Automatic Liquid Pail Filling Machine for Paint is designed to efficiently and accurately fill paint pails (typically 1L to 20L) at high speeds while maintaining precision and safety. These machines are ideal for medium to large-scale paint manufacturing operations, where semi-automation balances cost-effectiveness with productivity. Below is a detailed overview of the machine's features, functionality, and benefits:

Key Features of the Semi-Automatic Liquid Pail Filling Machine:

High-Speed Filling:

Capable of filling up to 10-15 pails per minute, depending on the viscosity of the paint and the size of the pail.

Designed for continuous operation with minimal downtime.

Accurate Filling by Weight or Volume:

Uses load cells or mass flow meters to ensure precise filling by weight, with an accuracy of ±0.1%.

Alternatively, volumetric filling is available for less viscous products.

Viscous Product Handling:

Equipped with high-flow pumps and wide-bore hoses to handle thick, viscous paints without clogging.

Optional heated hoppers or agitators to maintain consistent product flow and prevent settling.

Drip-Free Filling Nozzles:

Anti-drip nozzles and seal-off valves prevent drips and spills, ensuring clean and precise filling.

Nozzles are adjustable to accommodate different pail sizes and shapes.

User-Friendly Interface:

Touchscreen HMI (Human-Machine Interface) allows operators to set filling parameters, such as target weight, filling speed, and pause times.

Displays real-time data (e.g., fill weight, production count, and error alerts).

Safety Features:

Enclosed Cabinets or Hoods: Prevent paint fumes, spills, and splashes from escaping, protecting operators and the environment.

Emergency Stop Button: Quickly halts operation in case of emergencies.

Safety Interlocks: Prevent operation when doors or guards are open.

Stainless Steel Construction:

Made from 304 or 316 stainless steel for durability, corrosion resistance, and compliance with industry standards (e.g., FDA, ISO).

Easy to clean and maintain, ensuring hygiene and longevity.

Modular Design:

Can be customized to accommodate different pail sizes (e.g., 1L, 5L, 10L, 20L) and shapes.

Scalable for future expansion (e.g., adding more filling heads or integrating with other packaging equipment).

Lid Sealing System (Optional):

Automates the placement and sealing of pail lids.

Includes crimping tools for secure, airtight closures.

Data Integration (Optional):

Compatible with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) software for traceability and quality control.

Optional barcode or RFID scanners for tracking batch numbers, expiration dates, and product details.

Functionality of the Semi-Automatic Filling Machine:

Operator Loading:

The operator manually places empty pails under the filling nozzle.

Pais can be pre-positioned on a conveyor or pallet for faster operation.

Filling Process:

The machine dispenses the exact amount of paint into the pail using load cells or flow meters.

Filling speed and weight are adjustable to match the viscosity of the paint and the size of the pail.

Drip-Free Finish:

The anti-drip nozzle ensures a clean finish, preventing spills or drips onto the pail or work surface.

Optional Lid Sealing:

If equipped with a lid sealing system, the machine automatically places and seals the lid onto the pail after filling.

Unloading:

Filled pails are manually removed by the operator or placed on a conveyor for transport to the next stage (e.g., labeling, capping, or palletizing).

Benefits of the Semi-Automatic Filling Machine:

Cost-Effective:

Requires less upfront investment compared to fully automatic systems, making it suitable for medium-scale operations.

Reduces labor costs by automating the filling process while still allowing for manual oversight.

Precision and Consistency:

Ensures uniform filling weights and volumes, improving product quality and customer satisfaction.

Reduces variability in manual filling processes.

Product Integrity:

Drip-free nozzles and airtight seals protect paint from contamination and evaporation.

Reduces product waste and maintains cleanliness.

Flexibility:

Suitable for a wide range of pail sizes (e.g., 1L, 5L, 10L, 20L) and paint types (e.g., water-based, oil-based, specialty paints).

Adjustable settings allow for quick changes between products or batches.

Operator Safety:

Enclosed cabinets and safety features protect operators from hazardous fumes, spills, and splashes.

Reduces workplace accidents and health risks.

Ease of Use:

User-friendly interface and intuitive controls make operation simple, even for less experienced staff.

Minimal training required to operate the machine effectively.

Compliance:

Meets stringent environmental and safety regulations (e.g., ISO, OSHA).

Ideal for industries requiring traceability and quality control.

Sustainability:

Energy-efficient components (e.g., low-power motors, LED lighting) reduce energy consumption.

Compatible with recycled or reusable containers for sustainable packaging solutions.

Applications:

Paint Manufacturing: Ideal for filling water-based, oil-based, and specialty paints into pails.

Coatings and Varnishes: Suitable for filling wood stains, varnishes, and industrial coatings.

Adhesives and Sealants: Perfect for filling viscous adhesives and sealants into pails.

Chemicals and Solvents: Useful for filling industrial chemicals, thinners, and solvents.

Food and Beverage: Can be used for filling edible oils, syrups, and other food-grade liquids.

Why Choose This Semi-Automatic Filling Machine?

This high-speed semi-automatic liquid pail filling machine offers a balanced solution for paint manufacturers seeking efficiency, precision, and safety without the high cost of full automation. Its ability to handle viscous products, customize filling parameters, and ensure operator safety makes it an ideal choice for medium to large-scale paint filling operations. Whether you're looking to improve consistency, reduce labor costs, or enhance sustainability, this machine provides a reliable and versatile solution for your paint filling needs.

Immediate Order:

Website: http://www.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Small Semi-Auto Bottle Honey Juice Chili Sauce Filling Semi Auto Ink[2025-05-06]

-

Semi Auto Metal Pail/Tin Filling Machine for 1-30L High Viscous Liquid Filling[2025-04-01]

-

30L Double-Head Chemical Solvent Explosion-Proof Filling Line[2025-04-03]

-

Fully Automatic 1 Nozzle Automatic Checkweighing Automotive Ink & Chemical Raw Material Liquid 30L Can Filling Machine[2025-05-07]