Antifreeze Filling Machine 304 Stainless Steel Material Multi-speed Filling Flexible Operation Simple Maintenance

An Antifreeze Filling Machine constructed with 304 Stainless Steel Material, featuring Multi-speed Filling, Flexible Operation, and Simple Maintenance, is a robust and efficient solution for filling antifreeze, coolants, and other automotive or industrial liquids. Below is a detailed overview of this machine, its features, benefits, and key considerations for your application.

Key Features:

304 Stainless Steel Construction:

Safe for use with antifreeze, coolants, and other non-toxic liquids.

Made from 304 stainless steel, which is highly resistant to rust, chemical corrosion, and extreme temperatures—ideal for handling antifreeze and other harsh liquids.

Corrosion Resistance:

Food-Grade Compatibility:

Multi-Speed Filling:

Ensures accurate fill levels without spillage or overfilling, even with varying liquid flow rates.

Allows you to control the speed of filling based on the viscosity of the liquid, container size, or production requirements.

Adjustable Flow Rates:

Precision Filling:

Flexible Operation:

Pre-set fill volumes for different products or container sizes, ensuring consistency across batches.

Operator-controlled filling for small batches or integration into automated lines for higher throughput.

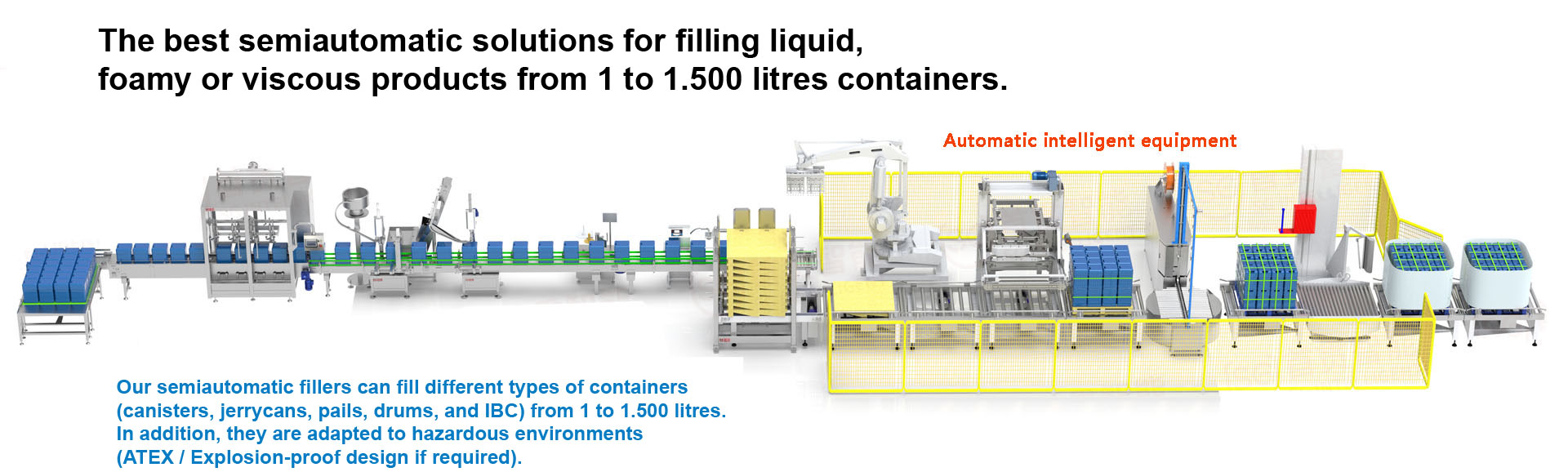

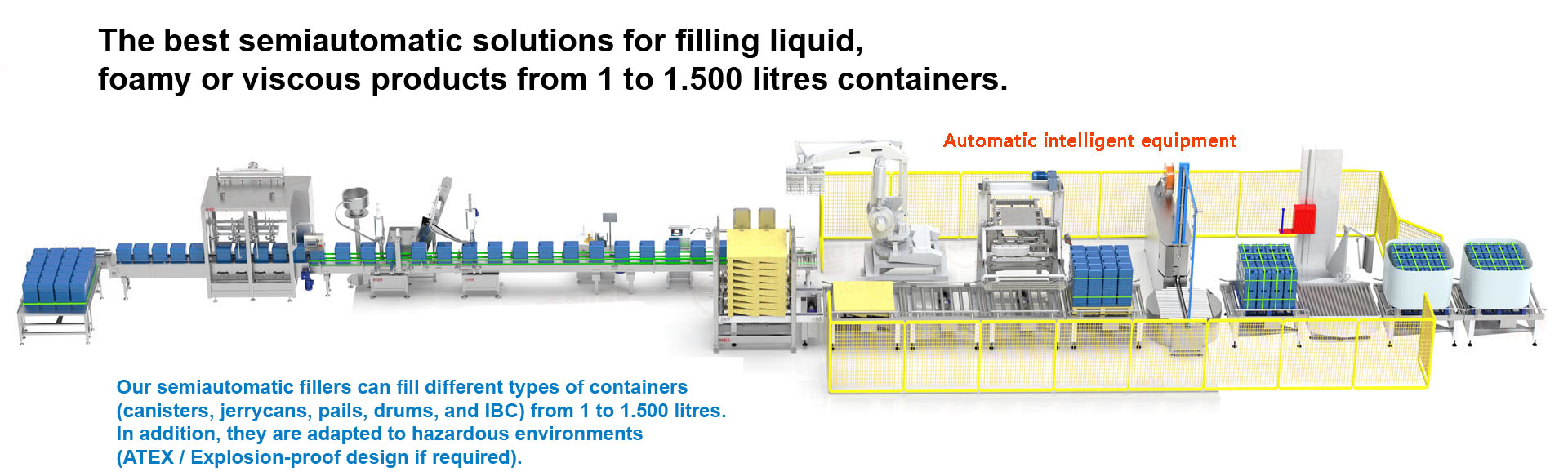

Suitable for filling bottles, cans, pails, or drums of various sizes (e.g., 1-5 gallons or larger).

Wide Container Range:

Manual or Semi-Automatic Modes:

Customizable Recipes:

Simple Maintenance:

Chemical-resistant seals and hoses reduce wear and tear, minimizing downtime.

Key components (e.g., pumps, valves, nozzles) are easily accessible for inspection, replacement, or maintenance.

Stainless steel surfaces and modular design allow for quick cleaning and sanitizing.

Easy Cleanup:

Accessible Parts:

Durable Seals and Hoses:

Safety Features:

Quickly halts operation in case of emergencies.

Automatically stops filling once the target level is reached, preventing overflow.

Prevents spills and leaks during filling, keeping the work area clean and safe.

Drip Trays:

Overfill Protection:

Emergency Stop:

User-Friendly Interface:

Simple buttons and dials for adjusting fill speed, volume, and other settings.

Shows real-time fill volume, target settings, and operational status.

Digital Display:

Intuitive Controls:

Optional Features:

Apply batch numbers, expiration dates, or barcodes for traceability.

Add automatic capping or sealing for fully automated workflows.

Automates container transport to and from the filling machine.

Inert gas purging to prevent foaming or oxidation (useful for volatile liquids).

Nitrogen Blanketing:

Integrated Conveyor:

Capping/Sealing Systems:

Labeling/Coding Systems:

Benefits for Your Business:

Corrosion Resistance:

304 stainless steel ensures longevity, even when handling harsh chemicals like antifreeze.

Versatility:

Handles a wide range of container sizes and liquid types (antifreeze, coolants, oils, etc.).

Precision and Consistency:

Multi-speed filling and adjustable flow rates ensure accurate fill levels every time.

Low Maintenance:

Easy cleanup and accessible parts minimize downtime and maintenance costs.

Scalability:

Start with a manual or semi-automatic machine and add upgrades (e.g., conveyor, capping system) as your business grows.

Safety and Compliance:

Drip trays, overfill protection, and emergency stop ensure a safe working environment.

Applications:

Antifreeze and Coolants:

Filling bottles, cans, or drums of antifreeze, engine coolants, or windshield washer fluid.

Automotive Fluids:

Filling motor oil, transmission fluid, or power steering fluid.

Industrial Chemicals:

Filling containers of industrial solvents, lubricants, or cleaning agents.

Food and Beverage:

Filling sauces, syrups, oils, or other viscous liquids (with food-grade materials).

Pharmaceuticals:

Filling non-hazardous liquid medications or lotions.

Operation Steps:

Container Placement:

The operator places an empty container under the filling nozzle manually or via a conveyor system.

Adjust Filling Settings:

Set the desired fill volume, flow rate, and other parameters using the digital interface.

Automatic Filling:

The machine starts filling at the pre-set flow rate, stopping automatically once the target volume is reached.

Sealing/Capping (Optional):

After filling, the operator manually places a lid or cap on the container and tightens it securely.

Alternatively, integrate an automatic capping system for full automation.

Discharging:

Filled containers are moved to the next stage (e.g., labeling, packaging) manually or with a conveyor system.

Cleanup:

Drip trays and sealed components minimize spills, making cleanup quick and easy.

Considerations When Purchasing:

Liquid Viscosity:

Ensure the machine can handle the viscosity of your liquids (e.g., thin antifreeze vs. thick coolants).

Container Sizes:

Choose a machine that accommodates the sizes of your containers (e.g., small bottles, pails, or drums).

Accuracy Requirements:

Select a machine with the appropriate level of precision (e.g., ±0.5% for high-precision applications).

Output Needs:

Determine the number of containers you need to fill per hour and choose a machine with the appropriate speed.

Customization Needs:

Consider additional features like nitrogen blanketing, coding systems, or integration with other equipment.

Budget:

Balance cost with features; start with a basic model and add upgrades as needed.

Training and Maintenance:

Ensure the machine is easy to operate and maintain, with accessible spare parts and support.

Safety Regulations:

Ensure the machine complies with local safety standards for handling chemicals or flammable liquids.

Why Choose This Machine?

A 304 Stainless Steel Antifreeze Filling Machine with multi-speed filling, flexible operation, and simple maintenance is a reliable and efficient solution for businesses involved in filling antifreeze, coolants, and other liquids. Its corrosion-resistant construction ensures longevity, while its precision and versatility make it ideal for a wide range of applications. By investing in this machine, you can improve productivity, reduce waste, and ensure consistent product quality—all while maintaining the flexibility to scale your operations as your business grows.

Immediate Order:

Website: http://www.360banjia.cn/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com